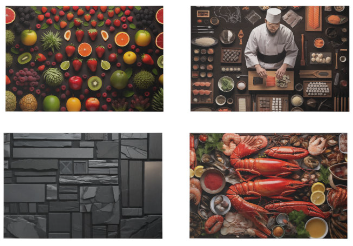

The art of knolling chocolates is as much about the presentation as it is about the chocolates themselves. Imagine a large, flat surface where assorted chocolates are meticulously organized at 90-degree angles, creating a visually stunning and orderly display. This methodical arrangement not only showcases the variety and beauty of the chocolates but also reflects the precision and care that goes into making each piece.

The Knolling of Chocolates: A Display of Diversity and Craft

In this knolling, each type of chocolate - whether it be dark, milk, or white - is given its own space, allowing onlookers to appreciate the differences in color and texture. Truffles, pralines, ganaches, and chocolate-covered fruits are grouped according to their kind, creating an aesthetically pleasing pattern. Accompanying these are various tools of the chocolatier’s trade: molds, dipping forks, spatulas, and tempering machines, all laid out in perfect alignment.

The Chocolate Making Process: From Bean to Bar

The journey of chocolate from its raw form to the finished product is a fascinating process, involving several key steps:

-

Harvesting and Fermenting: Chocolate making begins with the harvesting of cacao pods from the cacao tree. The pods are cut open to extract the cacao beans, which are then fermented for several days. Fermentation is crucial as it develops the beans' flavors.

-

Drying and Roasting: After fermentation, the beans are dried and then roasted. Roasting further develops the chocolate flavor and color. The roasting process varies depending on the desired flavor profile.

-

Cracking and Winnowing: The roasted beans are cracked to separate the nibs from the shells. The nibs contain the essence of the chocolate flavor. Winnowing removes the shells, leaving behind the pure cacao nibs.

-

Grinding and Refining: The nibs are then ground into a paste

known as chocolate liquor or cocoa mass. This paste is further refined to achieve a smooth texture. The refining process is critical as it determines the final texture of the chocolate.

-

Conching: Conching is a process of heating and mixing chocolate liquor. It's an essential step that develops the final flavor and texture of the chocolate. During conching, any residual moisture evaporates, and the chocolate becomes smoother.

-

Tempering: Tempering chocolate involves carefully heating and then cooling the chocolate to stabilize it for making candies and confections. Proper tempering gives chocolate a smooth, glossy finish and a crisp snap when broken.

-

Molding and Cooling: The tempered chocolate is poured into molds and cooled. This process shapes the chocolate into bars or other forms. After cooling, the chocolates are demolded and are ready for consumption or further decoration.

Conclusion: The Art and Science of Chocolate Making

The knolling of chocolates is a tribute to the entire chocolate-making process, showcasing the end products of a complex and delicate craft. Each piece of chocolate, with its unique flavor and texture, represents a journey from the tropical cacao fields to the chocolatier’s workshop. This artful display is not just a feast for the eyes but also a celebration of the art and science of chocolate making, inviting us to appreciate the intricate journey of each delectable piece.